The process calculation in the wastewater treatment field is the heart of every project and, especially for what concerns the biological treatments, which entail to deal with the complexity of life, it often turns out to be uncertain. The reason of this incertitude can be resumed as follows:

• Specificity of the formulas: the development of formulas is related to specific plant configurations (ex: pre-denitrification followed by an oxidation section with sludge and mixed liquor recirculation). More in detail this issue occurs in the following cases:

– Existing plants which, undergoing revamping and following adjustments, are characterized by particular configurations which the conventional formulas cannot be applied.

– Design of atypical configurations developed on specific customer needs/requirements.

• Steady state development: formulas reported in manuals are generally developed in order to give responses at steady state conditions, which are not applicable to dynamic contexts such as:

– Varying inlet flowrate and concentrations.

– Aeration temporization or implementation of intermittent aeration logics.

– Dynamic dissolved oxygen setpoints.

– Others.

• Simulation of complex processes affected by multiple operating conditions such as:

-Biological Phosphorus Removal (BPR) through Polyphosphate Accumulating Organisms (PAOs) growth.

–Nitrite accumulation due to imbalance between AOB (Ammonia Oxidizing Bacteria) and NOB (Nitrite Oxidizing Bacteria) growths.

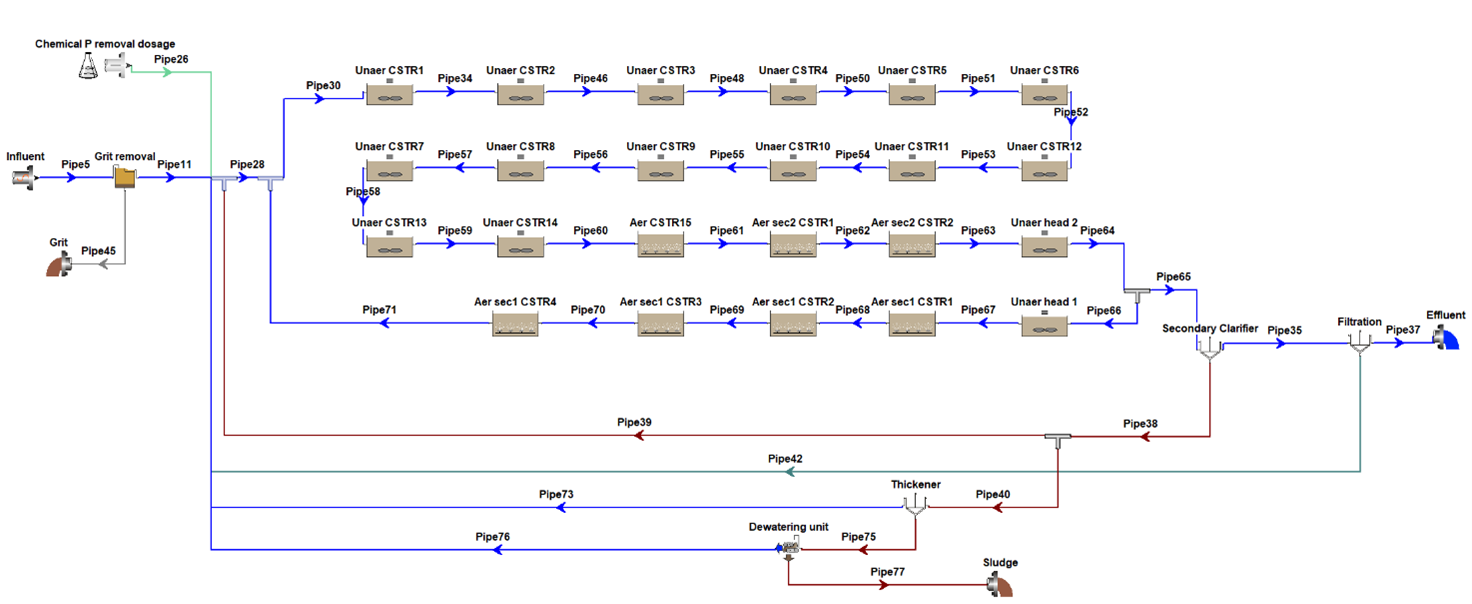

Figure 1: example of plant configuration shown through a simulation software

The modelling of the plants through a simulation software turns out to be a newly available tool for the wastewater treatment process engineers, which shows to be fundamental in order to reduce the impact of the simplifications usually introduced by the conventional calculation methods. Therefore, needs to better clarify the following points: