For many plant configurations the reproduction of the DO mass balance is a key factor to properly determine the biological reactors efficiency in terms of pollutants removal, like in the following cases:

- Configurations with pre-denitrification followed by an oxidation section in which the mixed liquor recirculation ratio is particularly high (as for example in some Membrane BioReactors-MBRs). In these contexts, the amount of oxygen recirculated in the pre-denitrification tank might not be negligible causing a consistent reduction of the denitrification capacity;

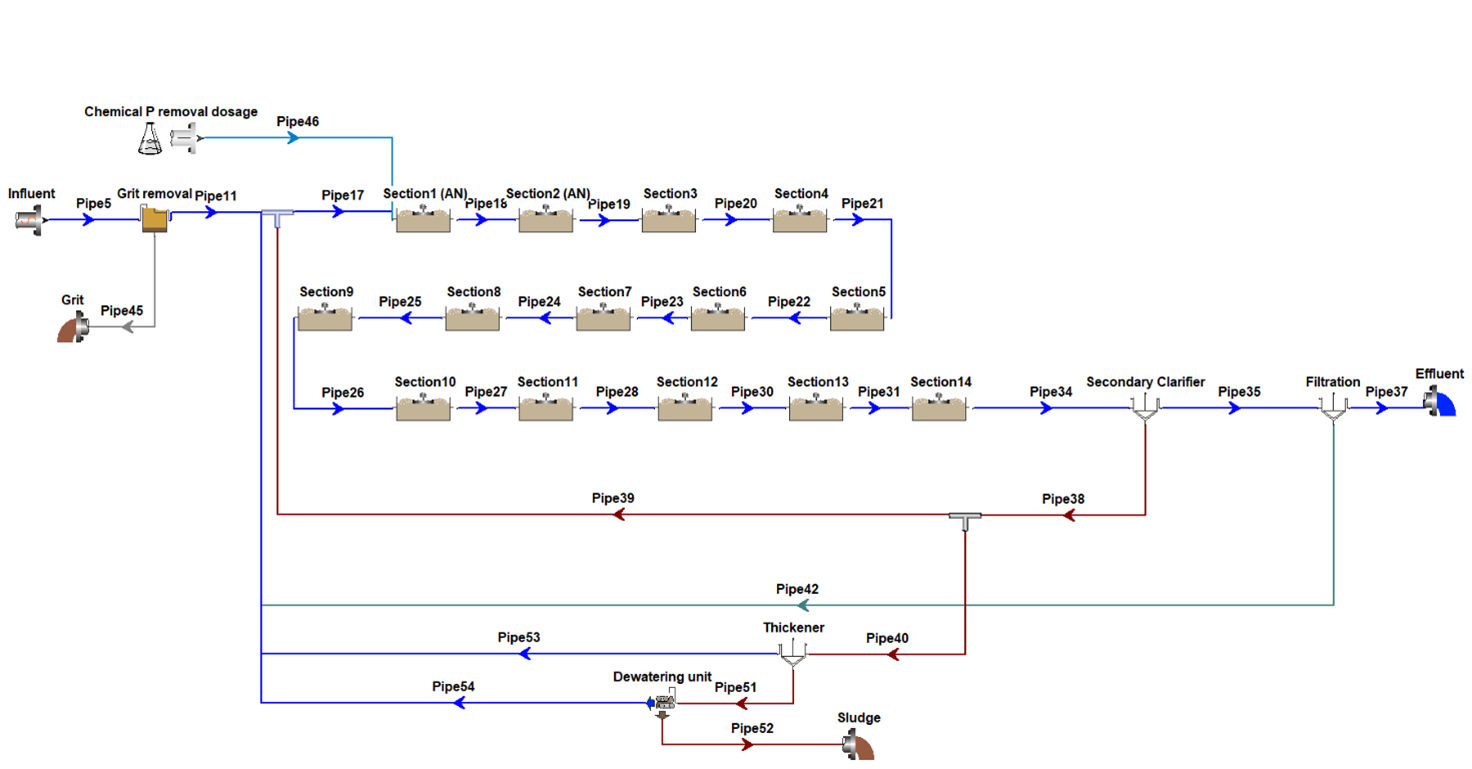

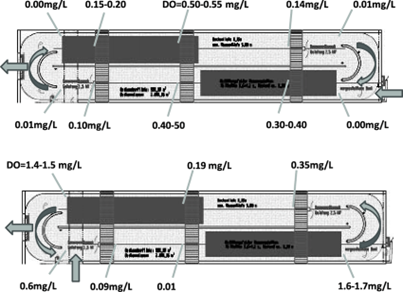

- Very long channel reactors characterized by aerated sections and unaerated ones in series, so generating DO concentration gradients which heavily affect the biological processes.

Figure 11: example of a very long channel reactor simulated as a series of CSTRs in which different DO concentrations are realized

Figure 11: example of a very long channel reactor simulated as a series of CSTRs in which different DO concentrations are realized

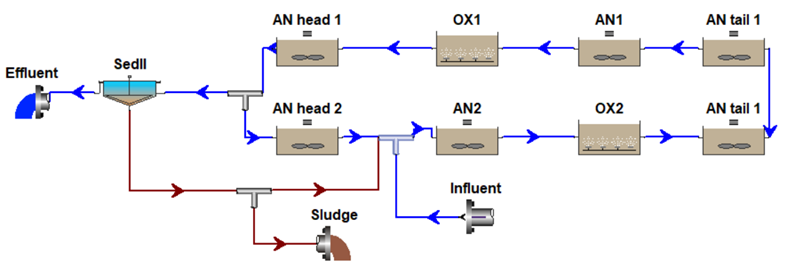

- Particular technologies such as carrousel like reactors in which, further than the reproduction of the DO gradient, it is fundamental to correctly simulate the points where the wastewater enters the plant reactor and where the treated water exits, as well as the internal recirculation (that in this kind of plants can be consisting on tens or even hundreds times the average inlet flowrate with a great impact on the biological processes)

Figure 12: example of carrousel like reactors characterized by DO gradients

Figure 13: example of model layout concerning a carrousel like reactor in which the DO gradient is reproduced, as well as the internal recirculation flowrate and the correct inlet and outlet points

Simulating the plant through a software allows to specify the DO concentrations in every aerated reactor as well as all the recirculation flowrates, correctly reproducing the DO transport towards the unaerated reactors and so estimating the effect of the incoming DO load.