The BPR represents the main process for the reduction of the chemical consumption related to phosphorus removal, since the more P is removed through biological accumulation the rest has to be removed through chemical precipitation. The increasing cost of the chemicals (ferric chloride, aluminium sulphate etc..) pushes more and more towards process configurations which maximize the above mentioned BPR getting a consistent reduction of the opex.

PHOSPORUS ACCUMULATION MECHANISM

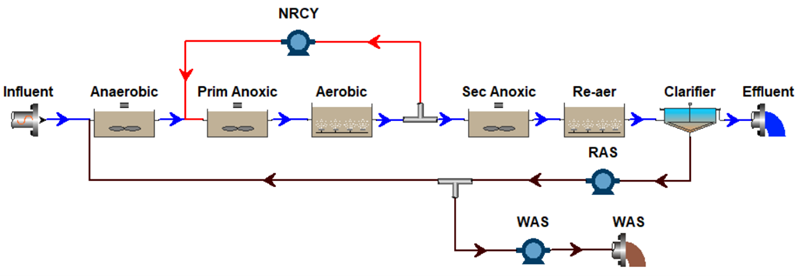

The BPR is based on the Polyphosphate Accumulating Organisms (PAOs) growth with are bacterial communities able to store the phosphorus inside the cells. This accumulation occurs through the selection of the heterotrophs making them undergo an alternance of aerobic and anaerobic phases. Essentially it is necessary to introduce an anaerobic compartment at the beginning of the treatment line which, apart from the wastewater to be treated, must receive only the sludge recirculation flowrate in order to get zero concentrations in terms of DO and NOx. In this way, after the aerobic conditions of the oxidation tank, the PAOs are recirculated to the anaerobic compartment undergoing the above mentioned alternance of aerobic and anaerobic phases.

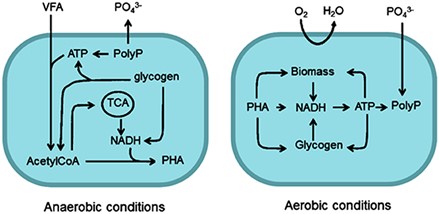

During the aerobic phase the presence of DO and nitrogen oxides to use as electron acceptors allows the PAOs to exploit the readily biodegradable COD available in the environment for their energetic metabolism and, at the same time, to store polyphosphate (Poly-P) and COD (in the form of polyhydroxyalkanoates-PHA) inside the cells. This process allows to remove from the water much more phosphorus than that required for just for the biomass synthesis, thus reducing the need of chemicals for the phosphate precipitation. During the anaerobic phase the lack of electrons acceptors does not allow the heterotrophs to use the biodegradable carbon present in the environment, so the ordinary heterotrophs growth is inhibited while the PAOs are still able to grow (here occurs the selection of the PAOs). Indeed, even without electrons acceptors, the PAOs can exploit the Poly-P and the PHA for the energetic metabolism releasing phosphate in the environment. The alternance of aerobic and anaerobic conditions pushes the PAOs to maximize the Poly-P (and so phosphorus) and PHA accumulation in order to survive in the repeated anaerobic phases and thus in the absence of electrons acceptors.

The PAOs’ growth and so the efficiency in terms of BPR is then strongly affected by the following factors:

• Number of aerobic-anaerobic cycles which the biomasses undergo as a function of the sludge recirculation flowrate and the SRT;

• Availability of readily biodegradable carbon (rbCOD) in the environment in aerobic conditions;

• Volume of the anaerobic compartment;

• The presence of anaerobic zones right before the outlet point could cause the release of phosphate by the PAOs. This is for example the case of big secondary clarifier with thick sludge beds inside which anaerobic conditions are realized, or it is also the case of post-denitrification tanks in which very low NOx concentration occurs, creating an almost anaerobic environment;

Figure 4: scheme of the BPR process (Bunce et al., 2018)

WHY IS IT FUNDAMENTAL TO IMPLEMENT AN ASM THROUGH A SIMULATION SOFTWARE IN ORDER TO GET A CORRECT ESTIMATION OF THE BPR PROCESS?

The conventional calculation methods don’t allow a real estimation of the PAOs’ growth, merely allowing to increase the specific phosphorus requirement parameter related to the biomass synthesis, which literature range is quite wide. In general, the literature only suggests providing an anaerobic volume of about 10% of the total biological volume available. The most recent ASMs are provided with specific process equations for the description of the PAOs’ growth with parameters calibrated on experimental data, such as specific half saturation constants for each substrate (rbCOD, Poly-P, calcium, magnesium etc…), growth reduction factors related to anoxic and anaerobic conditions, decay rates for aerobic/anoxic and anaerobic conditions etc…Applying these models through a software simulation allows to specify exactly the plant configuration getting an estimation of the conditions in every part of the plant (concentration of rbCOD, DO, nitrogen oxides, SRT, HRT etc…) and, on these conditions basis, obtaining an estimation of the PAOs’ concentration in the reactors and the related Poly-P accumulation inside the cells.

Essentially the calculation through a software allows to get the results as a function of all the previously listed factors.

WHICH CONTEXT DOES THE CALCULATION THROUGH A SIMULATION SOFTWARE GIVE FUNDAMENTAL ADVANTAGES TO?

In terms of design and process evaluation, a simulation software allows to:

- For an existing plant:

- Calibrating the parameters of the model it is possible to simulate the present state of the plant reproducing its behaviour at average conditions and getting an estimation of all the concentrations in every compartment;

- Starting from the present state model, it’s possible to check if the conversion of a part of the plant into an anaerobic volume could bring a reduction of the chemical consumption for the P removal, getting an estimation of this save;

- Once added the anaerobic volume to the model it’s also possible to modify the operating conditions (sludge extraction from the secondary clarifier, sludge recirculation flowrate, excess sludge extraction etc…) in order to maximize the BPR;

- Checking that no anaerobic conditions occur at the end of the treatment line in order to avoid phosphate release before the outlet point;

- If the recirculation of water incoming from the dewatering of anaerobic sludge is present, it is possible to get an estimation of the impact of the recirculation on the outlet concentrations. In fact, the anaerobic conditions realized in the digesters often cause the release of phosphates by the PAOs, which phosphates are then recirculated at the beginning of the wastewater treatment line. This effect is often not considered but it may cause a strong reduction of the benefits provided by applying the BPR process (as much P is accumulated by the PAOs as much is released in the anaerobic digesters and so recirculated in the WWTP creating a loop);

- If a respirometry is available, it’s also possible to get an estimation of the effect of the inlet COD fractionation and thus of the availability of rbCOD, also considering the SRT and the hydrolysis processes;

All the above explained advantages are still valid for the design of new plants consistently reducing the hazard in terms of process evaluation